|

|

|

|

|

|

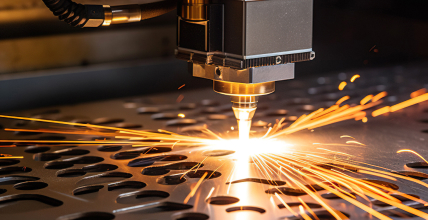

Laser Cutting & Metal Bending

|

| Through refined techniques, including the use of computer-aided CNC machinery, we shape metals into precise configurations, meeting rigorous specifications and fulfilling the most exacting requirements before they move on to the next manufacturing phases or assembly.

|

|

|

| Laser cutting and metal bending are the initial and key stages in our metal manufacturing process. Beginning with raw materials like plates, sheets, rods, and bars, we employ laser-cutting machinery to cut shapes and designs. Subsequently, our skilled team utilises specialised equipment to further shape and bend the metal, crafting metal parts and semifinished metal products for diverse applications.

|

|

|

|

|

|

|

|

|

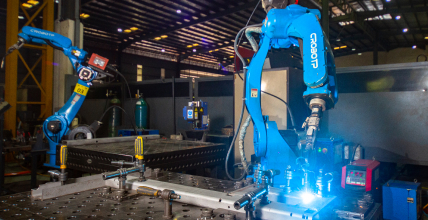

Welding

|

| As a part of the metal fabrication process, welding acts as the essential technique that joins metal parts, creating durable structures. This technique is commonly employed in fabricating metal parts, particularly in materials like carbon steel (including electro-galvanised steel), stainless steel and aluminium.

|

|

|

| At Wentel Engineering, we leverage various CNC technology with our CNC robotic-arm welding machines, featuring MIG, TIG, and laser welding capabilities, supported by our team of certified welders.

|

|

|

|

|

|

|

|

|

Structure Machining

|

| Our experienced team specialises in shaping, welding, milling, and machining materials such as steel, aluminium and stainless steel.

|

|

|

| Comprising a comprehensive range of machinery, our structure machining service is tailored to meet diverse requirements, including the fabrication of metal parts or semifinished products. Their applications extend across diverse industries such as semiconductor, medical, and more.

|

|

|

|

|

|

|

|

|

Surface Treatment

|

| The surface treatments that we carry out in-house include the following:

|

|

|

|

|

| Sandblasting

|

|

| Sandblasting uses high-pressure airflow to spray the surface with fine solid particles to remove rust and surface corrosion and create a smooth surface;

|

|

|

|

|

|

| Degreasing

|

|

| Degreasing with a detergent solution to remove oil and dirt from the metal surface;

|

|

|

|

|

|

| Buffing

|

|

| Buffing is carried out to remove surface residue and excess material; and

|

|

|

|

|

|

| Zinc Phosphate Treatment

|

|

| Zinc phosphate treatment of carbon steel items to inhibit rust formation and as a primer for subsequent powder coating.

|

|

|

|

|

|

|

|

|

|

Surface Coating

|

| Surface coating refers to the application of protective or decorative layers onto materials, safeguarding against corrosion, wear, and environmental damage while also enhancing aesthetics. Our in-house capabilities include:

|

|

|

|

|

| Zinc Electroplating

|

|

| Our zinc electroplating method offers robust corrosion protection, ensuring longevity and durability for your metal surfaces.

|

|

|

|

|

|

| Powder Coating

|

|

| With our powder coating service, we provide a durable & attractive finish, protecting surfaces from corrosion, abrasion, and fading.

|

|

|

|

|

|

| Spray Painting

|

|

| Our precise spray painting technique delivers even & consistent coverage, providing both protection & an appealing finish.

|

|

|

|

|

|

|

|

|

|

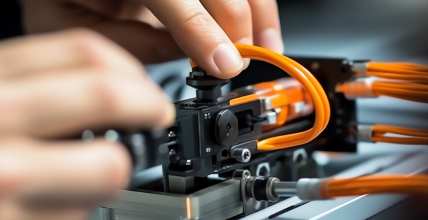

Assembly of Finished Products

|

| Our assembly of finished products segment produces walk-through metal detectors used for security screening applications. Working closely with our customers, we assemble materials from their approved suppliers along with our in-house fabricated aluminium plates to produce finished products that are operational and ready for use. This entire process is conducted in-house, adhering to the design and technical specifications provided by our customers.

|

|

|

| Our assembly process covers electrical, electronic and mechanical parts, components and systems as well as electrical wiring and processing system installation, and functional testing of the finished products.

|

|

|

|

|

|

|